Pectin has a wide applications in the food industry, as well as in the medical and pharmaceutical fields. In this article we review the methods for pectin extraction and their application.

By Maryam Vanaee, Cademix Institute of Technology and Pakshimi Farayand Company.

What is Pectin?

Pectin is a natural fiber found in several fruits and vegetables. Also, it works as a connective tissue between plant cells. Unripe fruits have the most pectin. In addition, Pectin is the major component of the white, spongy section of the fruit’s skin.

The flavor of this odorless material is similar to that of gum. It dissolves easily in water, especially warm water, and forms a clear colloidal liquid. Pectin decomposes in an alkaline environment, but it can be produced in an acidic one. Pectin is in fruits like apples, plums, cherries, and citrus fruits, as well as vegetables, like carrots, potatoes, sugar beets, tomatoes, and a variety of others. For instance,citrus peel and apple pulp are the most common raw materials used to produce pectin.

This substance, which is a soluble polysaccharide with long chains of indigestible sugars, expands under heat and turns into a gel. The gel-like state of pectin has led to its use in the food industry as an ideal thickening agent for a variety of jams and jellies. In addition to the food industry, the special physical state of this substance also use in the pharmaceutical industry; Because the gel-like properties of this compound in our digestive system provide countless benefits to us.

Type of pectin

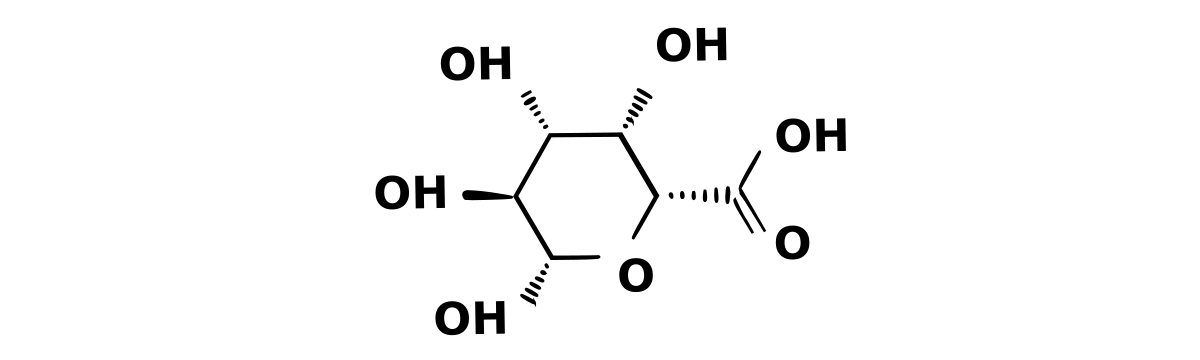

D-galacturonic acid is the most important component of the pectin. This acid, which has the molecular formula HOOC (CHOH) 4COOH or C6H10O7,is a key component of plant pectin. Pectin has a viscosity of between 3-6 deciliters per gram. Specifically, pectins are classified based on the degree of esterification. Pectin with a high esterification rate of more than 50% is high methyl ester (HM), and pectin with a methyl ester concentration of less than 50% is pectin with low methyl ester (LM).

According to their gel formation temperature, HM pectins are fast or slow set pectins. extraction procedure and condition influences on type of pectin. The reaction of HM pectins with ammonia produces amide pectins.(mostly LM)

How can we extract pectin?

We can extract pectin using peels by different method such as acid , microwave and enzymatic extraction.

in general adding dilute hot acid in the acidic pH range of 1.5 to 3.5 for several hours. the pectin is precipitated with the addition of ethanol or isopropanol. we can also use proteins and detergents to precipitation pectin. When we use ammonium hydroxide , intermediate pectin is produced. After all steps we dry and grind the pectin. For the best effectiveness, we standard pectin with sugar and organic acids.

Acid extraction of pectin

Acids are the most powerful pectin extracting agents because they allow for the extraction of insoluble pectin , resulting in higher yields. Acetic, citric, lactic, malic, tartaric (organic), hydrochloric, nitric, oxalic, phosphoric, and sulfuric acids are the most often preferred acids. Also increasing acid strength (that is, decreasing pH) helps to enhance galacturonic acid content. Furthermore, acid type and concentration have an impact on pectin production, physiochemical properties, and functional qualities .

for instance, among the hydrochloric, nitric, and citric acids extracted from guava peel, citrus fruits, bananas, and cocoa pods, hydrochloric acid yielded the most pectin. Temperature and pH ranged from 1 to 3 and 60°C to 85°C, respectively. The presence of a high concentration of hydrogen ions promotes pectin hydrolysis from proto pectin.

Because of their higher affinity for cations such as Ca2+, which stabilizes the pectin molecule, higher ionic strength acids have a better ability to precipitate pectin. Hydrochloric acid, on the other hand, produced pectin with a lower DM range than LM pectin . Due to its high acid lability and sensitivity, pectin degrades quickly in hot acid media. As a result of demethylation and fragmentation of the polygalacturonic chain, we have low methoxylated pectin with hot acid. Furthermore, LM pectin is found in a wide pH range, up to pH 6.

Extracting with citric acid has a lowest yield. according to some studies, the acid type had a significant influence on the macromolecular and gelling properties of isolated pectin. Citric acid has also the least pectin degrading (depolymerizing and de esterifying) extracting agent. Citric acid can produces pectin with improved gelling properties. Some studies, however, advocated for the use of citric acid due to its higher yield and higher quality than other acids.

Microwave extraction of pectin

Microwave Assisted Extraction involves dielectric heating of plant molecules via microwave exposure. Dipolar rotation of water occurs as a result of microwave energy absorption. Also it generates hot within the plant’s tissues. This method produces pectin with high quality and yield.

Enzymatic extraction of pectin

Enzymatic pectin extraction is both safer for the environment and more effective in terms of pectin yield. we can use enzymes such as polygalacturonase, hemicellulose, protease and microbial mixed enzymes, cellulose, -amylase, celluclast, alcalase and -amylase and neutrase, Xylase, cellulose, b-glucosidase, endopolygalacturonase, and pectinesterase in pectin extraction because enzymes have the ability to degrade pectin.

Pectin applications

The following are some of the uses for pectin:

- Jams and jellies: Pectin distributes the fruit evenly by creating a suitable consistency in the jams

- Canned food: Pectin in canned food causes proper viscosity in canned tissue.

- Baking items :Some baking products contain jelly kernels, the moisture and flavor of which must remain within the range of the dough that surrounds it. In order to maintain the boundary layer (between the dough and the marrow), the gel should not turn into a sol during heating. Pectin gels are thermally irreversible and are useful for this purpose. Thus, we can place the pre-prepared gel in the dough and bake the cake without worrying about lubrication.

- Confectionery products: Confectionery jellies make fruit made with pectin create a soft and desirable texture

- Meat product: Pectin improves cooking efficiency, reduces formulation costs and increases texture in food products

- use as Emulsifier: Citrus pectin with low molecular weight and high degree of methoxylation has a high emulsifying property and is able to stabilize oil-in-water emulsions (including mayonnaise).

- Medicine: Pectin prevents constipation and diarrhea by increasing the concentration and volume of feces and is very useful in preventing colon cancer and lowering blood cholesterol.

Keyword related to Pectin Extraction

Extraction, microwave, acid, enzymatic extraction, carbohydrate, polymer, boiling, solubility, degradation, carboxylic-acid, Strong-acid, Esterification, fibre, fiber.

About the Author

Maryam Vanaee with a master’s degree in chemistry in 2017 and immediately entered the related job market. She has worked as a director of resea rch and development at a private chemical company and has piloted many projects, including pectin. If you want to know more information please contact me by:

WhatsApp:+9809379080089

Email address: maryam1370.vanaee@gmail.com

LinkedIn account: maryam.vanaee

References

- A Review: Different Extraction Techniques of Pectin – Hilaris …

https://www.hilarispublisher.com ›