Cademix Institute of Technology

Job seekers Portal for Career Acceleration, Continuing Education, European Job Market

3D Printing Business Overview – Interview with Dr. Javaid Butt

- State of 3D Printing Technology?

- 3D Tech, Hype and reality comparison?

- What are the industrial skill sets related to 3D Tech?

- What are the business models for 3D Printing?

- Recommendations for SME Growth in 3D Tech?

- What are the challenges of the growing businesses?

How significant is the 3D Tech? Today vs. Future

3D Printing or Additive Manufacturing (AM) has created a massive impact on several industries including aerospace, automotive, medical etc., and will continue to push the boundaries of what is achievable. There are several commercially available AM methods that have been classified into seven categories. These categories are further sub-divided into different types depending on the operation flow, materials used and manufacturers. These AM processes have their own niche markets and are continuously being researched for improvements in terms of speed, materials, and geometry size. According to Wohlers Report 2018 (published by Wohlers Associates; preeminent AM experts in the world), AM has exceeded $7 billion ($7.3 billion) with a forecast of it hitting $10.8 billion by 2021. These are massive numbers and goes to show the impact that AM is continuously creating in the market. Variety of different materials are used in a predefined manner to manufacture products in metals, plastics, ceramics, etc., that makes AM an ideal choice for different industrial sectors such as aerospace, automotive, medical and electronics to name a few. AM offers several distinct advantages over other conventional manufacturing methods but perhaps the most important ones are design freedom and reduction in lead time from design conceptualization to prototyping. These advantages have paved the way for a competitive environment where innovation is the key. There are several growth drivers that can impact the uptake of AM depending upon the industrial sector. Design flexibility, reduced material costs, quick turnaround time at a fraction of the cost compared to traditional manufacturing, life cycle sustainability, enhanced/improved product functionality through practices such as part consolidation, minimization of carbon footprint, globalization of manufacturing services, topological optimisation (without compromising the product’s structural integrity), individualization and customization of products (that is becoming a trend these days), digitization of manufacturing (Industry 4.0 which brings in the idea of a ‘smart factory’ by combining AM with other areas such as Internet of Things, cloud computing, cyber security etc). These tempting growth drivers have resulted in corporations such as GE (General Electric), Siemens, Johnson & Johnson, BMW, etc., to invest millions of dollars in AM to develop and enhance their capabilities.

Is the 3D Tech news a mixture of Facts, Fictions, and Hype?

Facts, fiction, and hype go hand in hand in today’s market. Initially, the hype around AM was very strong and there were elements of fiction associated with it as well. However, AM is one of the few technologies that have made industries believe in the hype and has delivered on a massive scale. Hence the reason for its usage in industries worldwide. It should be noted that the major changes brought by AM took rigorous research over the years to enhance and integrate these methods in the manufacturing industry. One news that would seem like fiction but is quickly becoming a reality is the development of a universal language for Additive Manufacturing. Researchers at the University of Huddersfield in the UK are developing a new language to streamline the AM process from the design to the production stage. This could allow designers, engineers, technicians, and inspectors to communicate in an intelligent and robust manner by developing CAD (computer-aided design) models that can be exchanged among heterogenous CAD systems and eradicate the dependence on .stl and .obj file formats. Another aspect that has gained momentum due to the ever-increasing AM systems is the integration of different control software programs into a single platform. This would be particularly useful for companies operating different AM systems where they have a singular platform to control all their machines thus resulting in a sustainable and efficient operation. This is achieved to a certain extent by the implementation of Industry 4.0 strategies, but this area is still relatively new and requires more research before it could become as mainstream as Additive Manufacturing. Other aspects that are proving to be useful for AM are software packages that include AdditiveLab and PrintSys. The former allows simulation of multiple manufacturing scenarios fast and in a reliable manner whereas the latter optimizes the 3D printing workflow.

AM is making strides in the medical sector and even though 3D bioprinting has been able to print human organs, they are still not viable to be implanted. We are still years away from being able to 3D print human organs (e.g., kidneys, lungs, cornea, heart) but research is ongoing and has shown some good progress over the years. To date, a complete artificial 3D bio-printed organ has not been successfully made. However, many companies and research groups have been inching their way towards a fully functional 3D printed heart. For example, a Chicago-based company Biolife4D successfully demonstrated the actual bioprinting of a patch of human heart tissue in 2018. Biotech startup Pandorum Technologies, which focuses on tissue engineering, made history a few years ago by being the first Indian company to 3D-print human liver tissue for medical research. They have achieved a new milestone, having bio-engineered human cornea tissue to enable scarless healing of corneal wounds.

These advancements do blur the lines between fact and fiction but bioprinting of soft human tissue like structures and vascular networks is quickly becoming a reality due to the potential impact it could have on human lives.

What are the major skills required in 3D Tech?

Transferrable skills are of paramount importance and with the advent of Industry 4.0 (digitization of manufacturing), they have become more important than ever. For individuals interested in AM, it is crucial to have a holistic understanding of how the different processes work, their limitations and cost analysis. The following is a list of some commonly advertised skills for AM with job titles:

- CAD and design skills (Mechanical Design Engineer)

- Practical skills if working with AM systems (Manufacturing Engineer)

- Troubleshooting of the AM machinery (AM Maintenance Engineer/AM Technician)

- Experience of quality inspection procedures for AM (AM Quality Inspector)

- Communication skills/sales experience (Sales/Application Engineer)

- Software development skills (AM Software Engineer)

- Systems integration skills (AM Development Engineer)

3D Tech Recommendations for SMEs

SMEs need to understand their market and identify opportunities for growth before investing in AM. It is because of the fact that there are barriers to its uptake and no company should invest in a technology that they don’t fully understand or are capable of sustaining over time. Limitations such as high initial investment, skills shortage, and unavailability of standardized testing procedures can lead to companies opting for other manufacturing methodologies. However, AM has shown significant advantages over conventional manufacturing methods with design freedom and reduced material usage being at the top of the list. SMEs need to undertake realistic return on investment calculations by taking their objectives, project costs and benefits into consideration. This will allow them to understand the effect AM will have on their business in the long run. In short, SMEs should plan their journey and should start small with probably a desktop 3D printer (they have come a long way from the RepRap Darwin and RepRap Mendel) followed by a commercial 3D printer with better accuracy and finish. They can even source their 3D printer for other customers and offer design services. These two aspects can generate a new income source for them. Once they are able to justify the printing costs then they can expand and start mass scale production based on their product range. This way, it will be easier to control and transition the 3D printing workflow.

Good business models, value propositions or niche markets in 3D Tech.

3D Printing/Additive manufacturing is growing at a rapid pace and the global estimates for this technology are extremely profitable. This is a good time for fresh graduates to think about their future and identify their passions. Many start-ups have converted low-cost desktop DIY 3D printers into legitimate businesses. It is, however, crucial to understand that things will not happen overnight and that there is a long period of hard work that is required to develop your business ideas. Establishing a niche market is important as it will allow the fresh graduates to cater to specific customers. Staring on a marketplace like 3DHubs or Shapeways is a good idea and can be used as a launching pad. Offering services to B2B customers as well as design and prototyping services are also some viable options. Providing customization of specific items will be a good idea especially in today’s market where individualization is considered to be very important. 3D scanning services go very well with 3D printers as they can allow for a smoother transition from the design to the final product without having to draw the CAD drawing. Having a large initial investment can be problematic but if that is an option then 3D printing farms can be developed where a few dozen 3D printers can be set up to offer commercial 3D printing services to customers. Such a company could be similar to traditional print and copy kiosks where one can send a model by the internet, optionally ask for modification, and then 3D print and receive the product. Setting up online stores for small household items, jewelry, customized collectibles and figures, prosthetics, etc., can all lead to substantial gains provided a niche market has been established and good customer relations have been developed.

What are the main challenges of the growing businesses?

Additive Manufacturing (AM) has brought about a shift change in the mentality and thinking of equipment manufacturers and personnel involved in the manufacturing industry to ask questions about what makes this technology revolutionary. The answer is not straight forward because even though AM can provide several benefits, it is not always the appropriate choice for the manufacture of a product and the difficulty in making that decision is somewhat responsible for companies not adopting AM. In this context skills gap and the unavailability of manpower with the expertise to make an informed decision is a major barrier for companies. Lack of industry-wide standards (BSI/ASTM) is another issue as most of them are only a few years old with a large majority still under development by the governing bodies.

High capital investment costs are also a deterrent and they are not only limited to the AM systems capable of producing a part. They also include costs for the equipment and safety procedures to be put in place for pre/post processing, handling of the raw material and defined guidelines for material disposal. This is particularly evident when dealing with metal AM that makes of powder metal which is quite expensive depending on the type of alloy used for manufacture. Regulatory hurdles in many countries is another barrier that has recently acquired much attention due to the expiration of several patents pertaining to AM processes. This has brought about a timely discussion with the European Parliament (much like other parts of the world) has published a resolution (June 2018) titled ‘on three-dimensional printing, a challenge in the fields of intellectual property rights and civil liability’ to highlight the need for increased regulations. This is mainly due to the high demands of the industrial sector that has led to companies like 3D Systems, EOS, Stratasys and ARCAM to develop and release new systems every year. To match this inflow of new systems equipped with improved processing capabilities, the skills shortage is becoming a massive hurdle. Universities and even companies like EOS are offering short courses on AM systems that can give individuals some knowledge and understanding but these courses are focussed on certain systems and are therefore limited. Full-time courses from universities such as Anglia Ruskin, University of Nottingham and the University of Central Lancashire are offering courses that provide individuals with in-depth knowledge and understanding of the decision making aspects of AM rather than only the technical ones.

Dr. Javaid Butt, Please tell us about your works in the field of 3D Tech

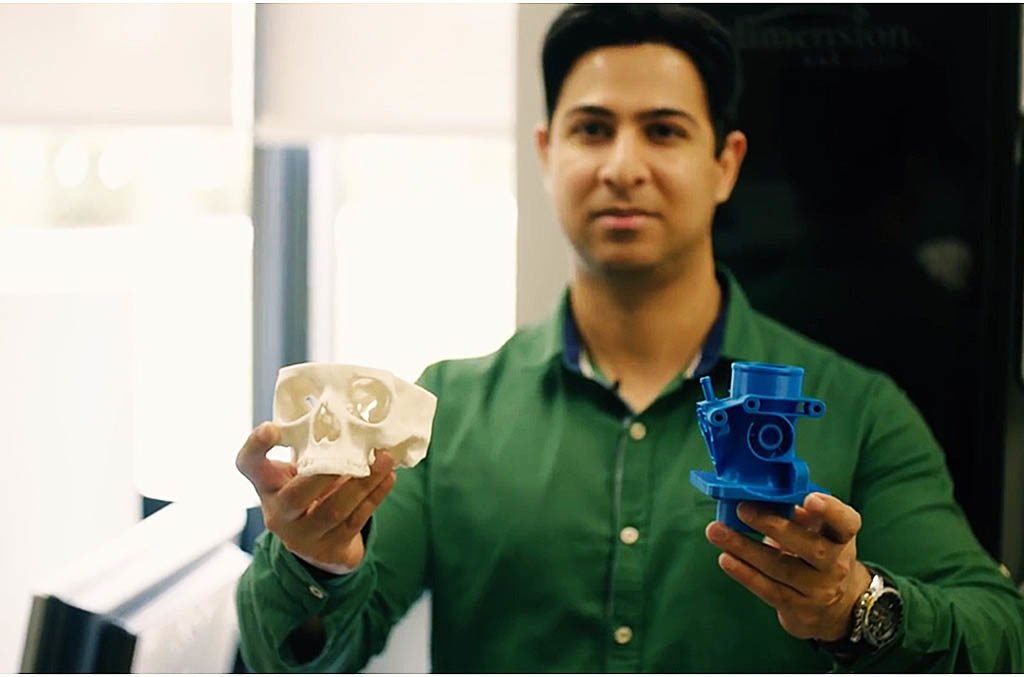

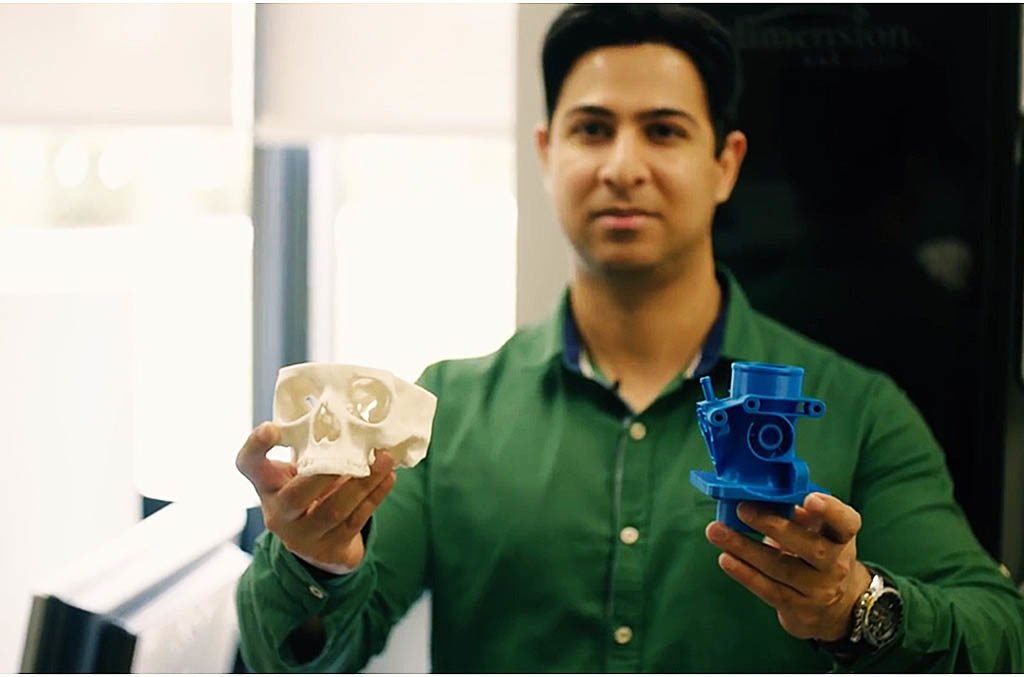

I am an expert in the field of 3D Printing/Additive Manufacturing and have been researching in this field for several years. I have designed, modeled and developed new AM systems capable of manufacturing products in plastics, metals, and composites (metal/metal and metal/plastic). I am well-versed and industrially trained for using AM/3D printing systems such as Dimension 1200es (Fused Depositing Modelling; commercial 3D printer from Stratasys), EOS M290 (Direct Metal Laser Sintering machine from EOS) alongside desktop-based 3D printers such as RS Pro IdeaWerk, Mendel, Mendel Prusa, and Anet A8/E12. I regularly design parts and print them for teaching and research purposes using the commercial and my own customized systems for material characterization and demonstration. I have an in-depth knowledge of the material properties and operating parameters of different AM systems that allow for the manufacture of products with the customized properties.

I am registered as an ‘Expert Advisor for Additive Manufacturing’ with two consultancy companies namely Guidepoint and Human Innovation that call upon my expertise from time to time. I have also given several invited talks on the subject matter (https://www.youtube.com/watch?v=e4lV5kmRMhE&feature=youtu.be). In 2017, I worked with industrial partners and played a vital role in the development, accreditation, and marketing of a new MSc course in Additive Manufacturing at Anglia Ruskin University (https://aru.ac.uk/study/postgraduate/additive-manufacturing) that was funded by HEFCE (Higher Education Funding Council for England). I supervised the marketing campaign and handled all the activities including the development of promotional material and narratives to be put on the university website, gave telephonic interviews to TCT Magazine (https://www.tctmagazine.com/locations/additive-manufacturing-msc-anglia-ruskin/) as well as working with the marketing team to shoot promotional videos demonstrating the use of our AM facilities and describing the course.

- https://www.youtube.com/watch?v=nBu2bZjs9CU

- https://www.youtube.com/watch?v=g8Am9BsQGtQ

- https://www.youtube.com/watch?v=_sSpTiKSw74

From a research standpoint, I have conceptualized, designed, and developed 4 different 3D printing systems to different Technology Readiness Levels (TRL) to manufacture a wide range of high-quality products. These systems include the following:

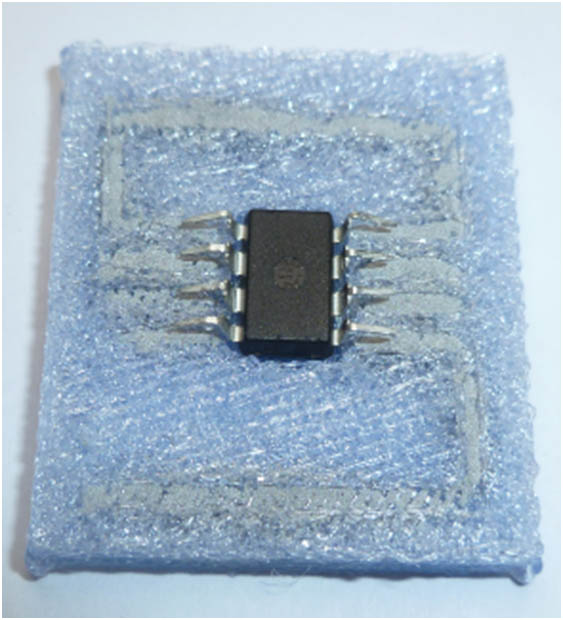

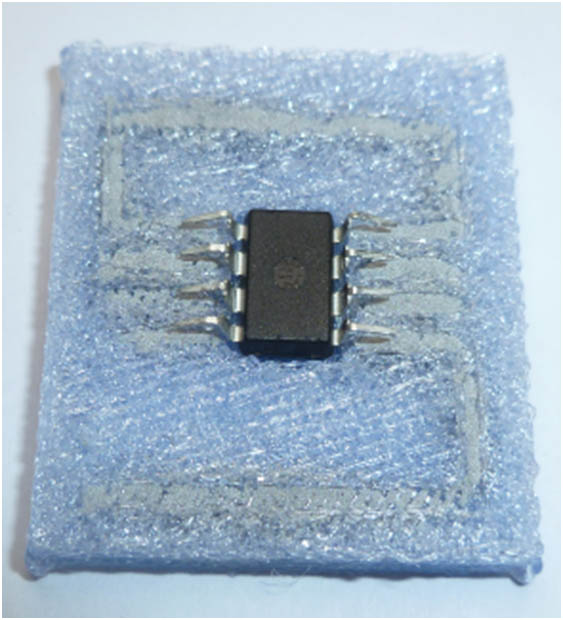

Desktop 3D printer with dual extruders to produce customized electronic circuitry (TRL 6/7)

This research is at TRL 6/7 and has been tested on several open source desktop 3D printers by the integration of an additional extruder. This low-cost enhancement to a desktop 3D printer can provide a new prospect to produce tailored electronic chips without the need for auxiliary equipment and processes. A variety of customized electronic circuits have been produced that are functional and ready for operation after minimal post-processing. The figures below show the customised 3D printer and the parts that have been made from it.

Production of Multiple Material Parts Using a Desktop 3D Printer (TRL 6/7)

This work is also at TRL 6/7 and has been prototyped for several open source desktop-based 3D printers by introducing new g-codes and modifying the main program. A separate powder dispenser has been specially designed that can dispense precise amounts of powder based on the programming. Plastic is dispensed from the extruder of the 3D printer and the powder dispenser can dispense powder which allows for an automated operation for the manufacture of multiple material parts with ease. The figures below show the customised 3D printer and the parts that have been made from it.

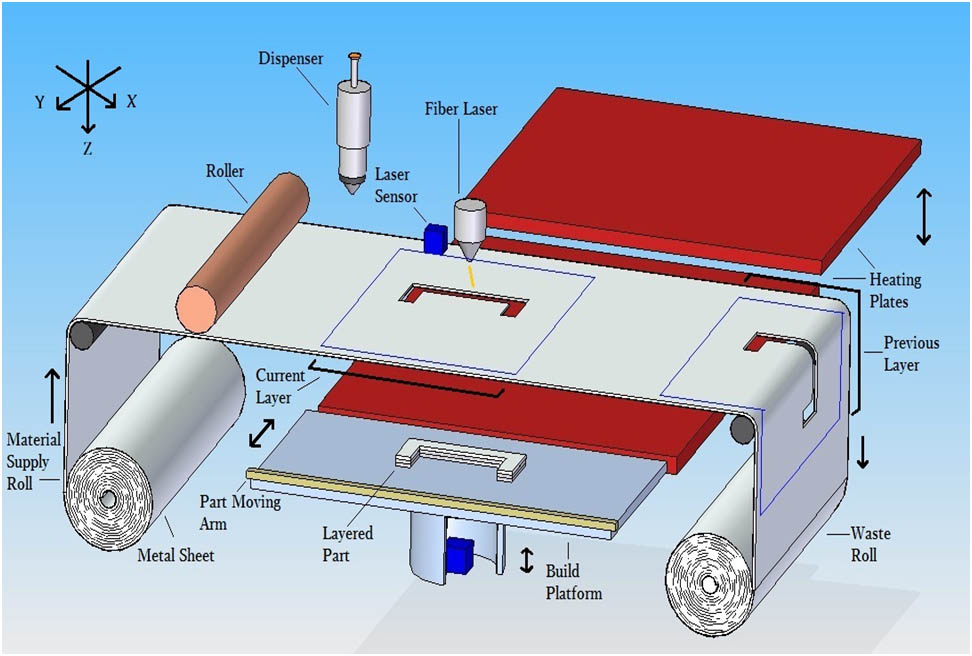

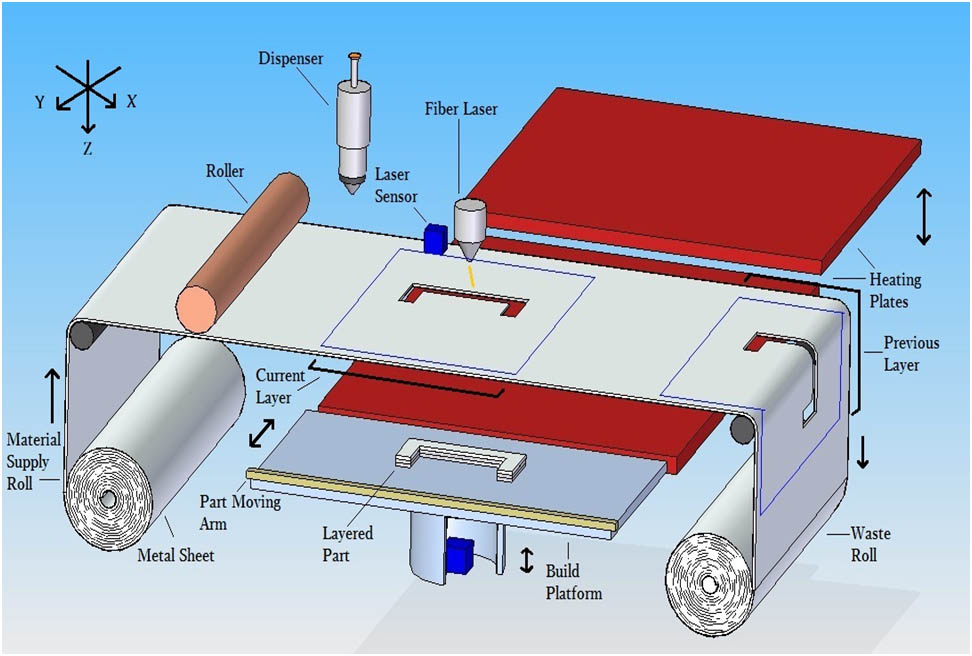

Composite Metal Foil Manufacturing (TRL 5/6)

This work is at TRL 5/6 and has been rigorously researched over the past 5 years for the manufacture of similar and dissimilar metal products. The process offers significant advantages over commercial metal additive manufacturing methods and has lessened the confinements associated with them, for example, cost, process speed, material determinations and beyond. Distinctive metals, such as copper and aluminium, with shifting thicknesses, were used to demonstrate the adaptability of the procedure. Composites of aluminium and copper were additionally delivered and tried for their mechanical properties to show the flexibility of the process. The outcomes of the research attained have been promising and show that the new process is not just fit for delivering astounding metal parts efficiently but can create more grounded parts contrasted with customary subtractive techniques. The comparative tensile testing demonstrated that the parts created by the composite metal foil manufacturing had fracture values that were 11%, 8%, and 11% higher than the parent copper, aluminium and composite examples individually. The feedback that parts delivered by added substance fabrication techniques are not sufficiently strong for genuine applications can without much of a stretch be hushed with the obtained trial results. Applications can extend from little bespoke parts to large scale functional products that can be utilized with minimal post handling. The figures below show the working principle of the CMFM process and the composites that have been made from it.

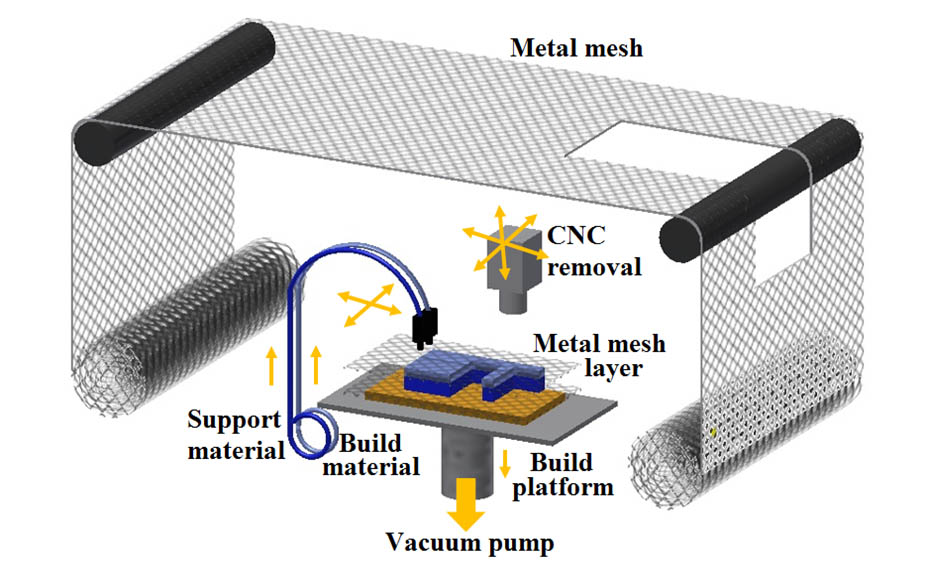

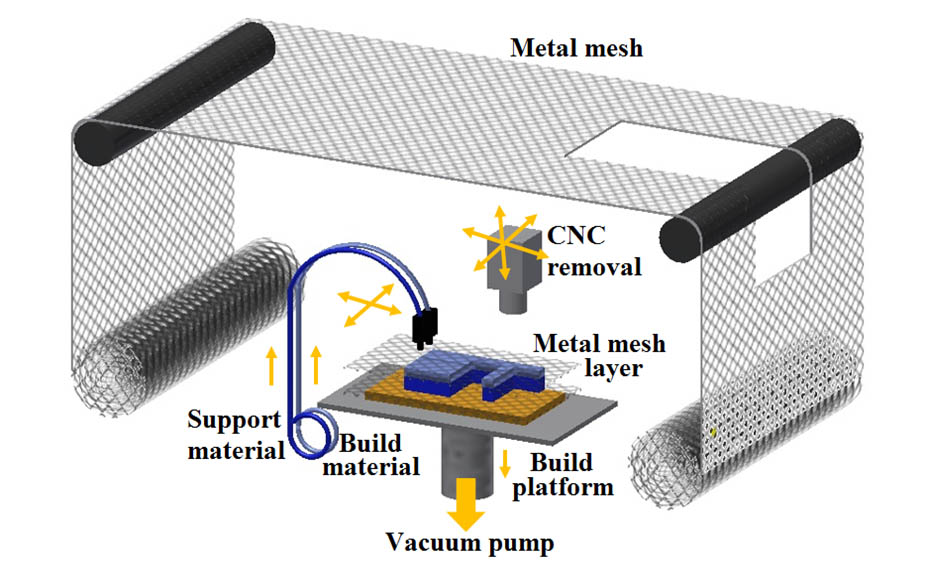

Hybrid Fused Deposition Modelling (TRL 5/6)

This is a new avenue of research to exploit the capabilities of Fused Deposition Modelling (a common additive manufacturing process) and is at TRL 5/6. This process allows for the manufacture of plastic/metal composites without using expensive and time-consuming adhesives or joining agents. Several specimens have been made and tested for their mechanical properties that show a gradual increase in fracture values with the addition of metal in mesh form. The process can be a strong candidate for the production of high-quality plastic/metal composites with tailored properties for specialized applications in the automotive and aerospace industries. The figures below show the working principle of the Hybrid Fused Deposition Modelling process and the composites that have been made from it.

Taken together, these activities clearly place me in the upper echelon with regards to academic and research activities in the field of 3D Printing/Additive Manufacturing. With the advent of new 3D printers and software packages, my expertise will continue to support and benefit the wider community.

References

- Butt, J., Ghorabian, M., Ahmed, A. and Shirvani, H., 2018. Finite element modelling and validation of thermomechanical behaviour for layered aluminium parts made by composite metal foil manufacturing. Journal of Composites Science, 2(4), p.68.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2018. Tensile lap-shear and flexural behaviour of aluminium metal foil parts made by composite metal foil manufacturing. Progress in Additive Manufacturing, pp.1-9.

- Butt, J., Shirvani, H., 2018. Experimental analysis of metal/plastic composites made by a new hybrid method. Additive Manufacturing, 22, 216–222.

- Butt, J., Onimowo, D.A., Gohrabian, M., Sharma, T. and Shirvani, H., 2018. A desktop 3D printer with dual extruders to produce customised electronic circuitry. Frontiers of Mechanical Engineering, 13(4), pp.528-534.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2018. Numerical and experimental analysis of product development by composite metal foil manufacturing. International Journal of Rapid Manufacturing, 7(1), pp.59-82.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2016. Microstructure and mechanical properties of dissimilar pure copper foil/1050 aluminium composites made with composite metal foil manufacturing. Journal of Materials Processing Technology 238, pp.96-107.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2016. Strength analysis of aluminium foil parts made by composite metal foil manufacturing. Progress in Additive Manufacturing, 1(1-2), pp.93-103.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2016. Rapid prototyping by heat diffusion of metal foil and related mechanical testing. The International Journal of Advanced Manufacturing Technology, 84(9-12), pp.2357-2366.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2015. Peel and tensile test investigation of aluminium 1050 foil parts made with a new additive manufacturing process. International Journal of Rapid Manufacturing, 5(1), pp.95-115.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2015. A novel rapid prototyping process for the production of metal parts. International Journal of Advancements in Mechanical and Aeronautical Engineering– IJAMAE, 2(1), pp.15-18.

Related Topics

People also visited:

3D Printing Business Overview – Interview with Dr. Javaid Butt

- State of 3D Printing Technology?

- 3D Tech, Hype and reality comparison?

- What are the industrial skill sets related to 3D Tech?

- What are the business models for 3D Printing?

- Recommendations for SME Growth in 3D Tech?

- What are the challenges of the growing businesses?

How significant is the 3D Tech? Today vs. Future

3D Printing or Additive Manufacturing (AM) has created a massive impact on several industries including aerospace, automotive, medical etc., and will continue to push the boundaries of what is achievable. There are several commercially available AM methods that have been classified into seven categories. These categories are further sub-divided into different types depending on the operation flow, materials used and manufacturers. These AM processes have their own niche markets and are continuously being researched for improvements in terms of speed, materials, and geometry size. According to Wohlers Report 2018 (published by Wohlers Associates; preeminent AM experts in the world), AM has exceeded $7 billion ($7.3 billion) with a forecast of it hitting $10.8 billion by 2021. These are massive numbers and goes to show the impact that AM is continuously creating in the market. Variety of different materials are used in a predefined manner to manufacture products in metals, plastics, ceramics, etc., that makes AM an ideal choice for different industrial sectors such as aerospace, automotive, medical and electronics to name a few. AM offers several distinct advantages over other conventional manufacturing methods but perhaps the most important ones are design freedom and reduction in lead time from design conceptualization to prototyping. These advantages have paved the way for a competitive environment where innovation is the key. There are several growth drivers that can impact the uptake of AM depending upon the industrial sector. Design flexibility, reduced material costs, quick turnaround time at a fraction of the cost compared to traditional manufacturing, life cycle sustainability, enhanced/improved product functionality through practices such as part consolidation, minimization of carbon footprint, globalization of manufacturing services, topological optimisation (without compromising the product’s structural integrity), individualization and customization of products (that is becoming a trend these days), digitization of manufacturing (Industry 4.0 which brings in the idea of a ‘smart factory’ by combining AM with other areas such as Internet of Things, cloud computing, cyber security etc). These tempting growth drivers have resulted in corporations such as GE (General Electric), Siemens, Johnson & Johnson, BMW, etc., to invest millions of dollars in AM to develop and enhance their capabilities.

Is the 3D Tech news a mixture of Facts, Fictions, and Hype?

Facts, fiction, and hype go hand in hand in today’s market. Initially, the hype around AM was very strong and there were elements of fiction associated with it as well. However, AM is one of the few technologies that have made industries believe in the hype and has delivered on a massive scale. Hence the reason for its usage in industries worldwide. It should be noted that the major changes brought by AM took rigorous research over the years to enhance and integrate these methods in the manufacturing industry. One news that would seem like fiction but is quickly becoming a reality is the development of a universal language for Additive Manufacturing. Researchers at the University of Huddersfield in the UK are developing a new language to streamline the AM process from the design to the production stage. This could allow designers, engineers, technicians, and inspectors to communicate in an intelligent and robust manner by developing CAD (computer-aided design) models that can be exchanged among heterogenous CAD systems and eradicate the dependence on .stl and .obj file formats. Another aspect that has gained momentum due to the ever-increasing AM systems is the integration of different control software programs into a single platform. This would be particularly useful for companies operating different AM systems where they have a singular platform to control all their machines thus resulting in a sustainable and efficient operation. This is achieved to a certain extent by the implementation of Industry 4.0 strategies, but this area is still relatively new and requires more research before it could become as mainstream as Additive Manufacturing. Other aspects that are proving to be useful for AM are software packages that include AdditiveLab and PrintSys. The former allows simulation of multiple manufacturing scenarios fast and in a reliable manner whereas the latter optimizes the 3D printing workflow.

AM is making strides in the medical sector and even though 3D bioprinting has been able to print human organs, they are still not viable to be implanted. We are still years away from being able to 3D print human organs (e.g., kidneys, lungs, cornea, heart) but research is ongoing and has shown some good progress over the years. To date, a complete artificial 3D bio-printed organ has not been successfully made. However, many companies and research groups have been inching their way towards a fully functional 3D printed heart. For example, a Chicago-based company Biolife4D successfully demonstrated the actual bioprinting of a patch of human heart tissue in 2018. Biotech startup Pandorum Technologies, which focuses on tissue engineering, made history a few years ago by being the first Indian company to 3D-print human liver tissue for medical research. They have achieved a new milestone, having bio-engineered human cornea tissue to enable scarless healing of corneal wounds.

These advancements do blur the lines between fact and fiction but bioprinting of soft human tissue like structures and vascular networks is quickly becoming a reality due to the potential impact it could have on human lives.

What are the major skills required in 3D Tech?

Transferrable skills are of paramount importance and with the advent of Industry 4.0 (digitization of manufacturing), they have become more important than ever. For individuals interested in AM, it is crucial to have a holistic understanding of how the different processes work, their limitations and cost analysis. The following is a list of some commonly advertised skills for AM with job titles:

- CAD and design skills (Mechanical Design Engineer)

- Practical skills if working with AM systems (Manufacturing Engineer)

- Troubleshooting of the AM machinery (AM Maintenance Engineer/AM Technician)

- Experience of quality inspection procedures for AM (AM Quality Inspector)

- Communication skills/sales experience (Sales/Application Engineer)

- Software development skills (AM Software Engineer)

- Systems integration skills (AM Development Engineer)

3D Tech Recommendations for SMEs

SMEs need to understand their market and identify opportunities for growth before investing in AM. It is because of the fact that there are barriers to its uptake and no company should invest in a technology that they don’t fully understand or are capable of sustaining over time. Limitations such as high initial investment, skills shortage, and unavailability of standardized testing procedures can lead to companies opting for other manufacturing methodologies. However, AM has shown significant advantages over conventional manufacturing methods with design freedom and reduced material usage being at the top of the list. SMEs need to undertake realistic return on investment calculations by taking their objectives, project costs and benefits into consideration. This will allow them to understand the effect AM will have on their business in the long run. In short, SMEs should plan their journey and should start small with probably a desktop 3D printer (they have come a long way from the RepRap Darwin and RepRap Mendel) followed by a commercial 3D printer with better accuracy and finish. They can even source their 3D printer for other customers and offer design services. These two aspects can generate a new income source for them. Once they are able to justify the printing costs then they can expand and start mass scale production based on their product range. This way, it will be easier to control and transition the 3D printing workflow.

Good business models, value propositions or niche markets in 3D Tech.

3D Printing/Additive manufacturing is growing at a rapid pace and the global estimates for this technology are extremely profitable. This is a good time for fresh graduates to think about their future and identify their passions. Many start-ups have converted low-cost desktop DIY 3D printers into legitimate businesses. It is, however, crucial to understand that things will not happen overnight and that there is a long period of hard work that is required to develop your business ideas. Establishing a niche market is important as it will allow the fresh graduates to cater to specific customers. Staring on a marketplace like 3DHubs or Shapeways is a good idea and can be used as a launching pad. Offering services to B2B customers as well as design and prototyping services are also some viable options. Providing customization of specific items will be a good idea especially in today’s market where individualization is considered to be very important. 3D scanning services go very well with 3D printers as they can allow for a smoother transition from the design to the final product without having to draw the CAD drawing. Having a large initial investment can be problematic but if that is an option then 3D printing farms can be developed where a few dozen 3D printers can be set up to offer commercial 3D printing services to customers. Such a company could be similar to traditional print and copy kiosks where one can send a model by the internet, optionally ask for modification, and then 3D print and receive the product. Setting up online stores for small household items, jewelry, customized collectibles and figures, prosthetics, etc., can all lead to substantial gains provided a niche market has been established and good customer relations have been developed.

What are the main challenges of the growing businesses?

Additive Manufacturing (AM) has brought about a shift change in the mentality and thinking of equipment manufacturers and personnel involved in the manufacturing industry to ask questions about what makes this technology revolutionary. The answer is not straight forward because even though AM can provide several benefits, it is not always the appropriate choice for the manufacture of a product and the difficulty in making that decision is somewhat responsible for companies not adopting AM. In this context skills gap and the unavailability of manpower with the expertise to make an informed decision is a major barrier for companies. Lack of industry-wide standards (BSI/ASTM) is another issue as most of them are only a few years old with a large majority still under development by the governing bodies.

High capital investment costs are also a deterrent and they are not only limited to the AM systems capable of producing a part. They also include costs for the equipment and safety procedures to be put in place for pre/post processing, handling of the raw material and defined guidelines for material disposal. This is particularly evident when dealing with metal AM that makes of powder metal which is quite expensive depending on the type of alloy used for manufacture. Regulatory hurdles in many countries is another barrier that has recently acquired much attention due to the expiration of several patents pertaining to AM processes. This has brought about a timely discussion with the European Parliament (much like other parts of the world) has published a resolution (June 2018) titled ‘on three-dimensional printing, a challenge in the fields of intellectual property rights and civil liability’ to highlight the need for increased regulations. This is mainly due to the high demands of the industrial sector that has led to companies like 3D Systems, EOS, Stratasys and ARCAM to develop and release new systems every year. To match this inflow of new systems equipped with improved processing capabilities, the skills shortage is becoming a massive hurdle. Universities and even companies like EOS are offering short courses on AM systems that can give individuals some knowledge and understanding but these courses are focussed on certain systems and are therefore limited. Full-time courses from universities such as Anglia Ruskin, University of Nottingham and the University of Central Lancashire are offering courses that provide individuals with in-depth knowledge and understanding of the decision making aspects of AM rather than only the technical ones.

Dr. Javaid Butt, Please tell us about your works in the field of 3D Tech

I am an expert in the field of 3D Printing/Additive Manufacturing and have been researching in this field for several years. I have designed, modeled and developed new AM systems capable of manufacturing products in plastics, metals, and composites (metal/metal and metal/plastic). I am well-versed and industrially trained for using AM/3D printing systems such as Dimension 1200es (Fused Depositing Modelling; commercial 3D printer from Stratasys), EOS M290 (Direct Metal Laser Sintering machine from EOS) alongside desktop-based 3D printers such as RS Pro IdeaWerk, Mendel, Mendel Prusa, and Anet A8/E12. I regularly design parts and print them for teaching and research purposes using the commercial and my own customized systems for material characterization and demonstration. I have an in-depth knowledge of the material properties and operating parameters of different AM systems that allow for the manufacture of products with the customized properties.

I am registered as an ‘Expert Advisor for Additive Manufacturing’ with two consultancy companies namely Guidepoint and Human Innovation that call upon my expertise from time to time. I have also given several invited talks on the subject matter (https://www.youtube.com/watch?v=e4lV5kmRMhE&feature=youtu.be). In 2017, I worked with industrial partners and played a vital role in the development, accreditation, and marketing of a new MSc course in Additive Manufacturing at Anglia Ruskin University (https://aru.ac.uk/study/postgraduate/additive-manufacturing) that was funded by HEFCE (Higher Education Funding Council for England). I supervised the marketing campaign and handled all the activities including the development of promotional material and narratives to be put on the university website, gave telephonic interviews to TCT Magazine (https://www.tctmagazine.com/locations/additive-manufacturing-msc-anglia-ruskin/) as well as working with the marketing team to shoot promotional videos demonstrating the use of our AM facilities and describing the course.

- https://www.youtube.com/watch?v=nBu2bZjs9CU

- https://www.youtube.com/watch?v=g8Am9BsQGtQ

- https://www.youtube.com/watch?v=_sSpTiKSw74

From a research standpoint, I have conceptualized, designed, and developed 4 different 3D printing systems to different Technology Readiness Levels (TRL) to manufacture a wide range of high-quality products. These systems include the following:

Desktop 3D printer with dual extruders to produce customized electronic circuitry (TRL 6/7)

This research is at TRL 6/7 and has been tested on several open source desktop 3D printers by the integration of an additional extruder. This low-cost enhancement to a desktop 3D printer can provide a new prospect to produce tailored electronic chips without the need for auxiliary equipment and processes. A variety of customized electronic circuits have been produced that are functional and ready for operation after minimal post-processing. The figures below show the customised 3D printer and the parts that have been made from it.

Production of Multiple Material Parts Using a Desktop 3D Printer (TRL 6/7)

This work is also at TRL 6/7 and has been prototyped for several open source desktop-based 3D printers by introducing new g-codes and modifying the main program. A separate powder dispenser has been specially designed that can dispense precise amounts of powder based on the programming. Plastic is dispensed from the extruder of the 3D printer and the powder dispenser can dispense powder which allows for an automated operation for the manufacture of multiple material parts with ease. The figures below show the customised 3D printer and the parts that have been made from it.

Composite Metal Foil Manufacturing (TRL 5/6)

This work is at TRL 5/6 and has been rigorously researched over the past 5 years for the manufacture of similar and dissimilar metal products. The process offers significant advantages over commercial metal additive manufacturing methods and has lessened the confinements associated with them, for example, cost, process speed, material determinations and beyond. Distinctive metals, such as copper and aluminium, with shifting thicknesses, were used to demonstrate the adaptability of the procedure. Composites of aluminium and copper were additionally delivered and tried for their mechanical properties to show the flexibility of the process. The outcomes of the research attained have been promising and show that the new process is not just fit for delivering astounding metal parts efficiently but can create more grounded parts contrasted with customary subtractive techniques. The comparative tensile testing demonstrated that the parts created by the composite metal foil manufacturing had fracture values that were 11%, 8%, and 11% higher than the parent copper, aluminium and composite examples individually. The feedback that parts delivered by added substance fabrication techniques are not sufficiently strong for genuine applications can without much of a stretch be hushed with the obtained trial results. Applications can extend from little bespoke parts to large scale functional products that can be utilized with minimal post handling. The figures below show the working principle of the CMFM process and the composites that have been made from it.

Hybrid Fused Deposition Modelling (TRL 5/6)

This is a new avenue of research to exploit the capabilities of Fused Deposition Modelling (a common additive manufacturing process) and is at TRL 5/6. This process allows for the manufacture of plastic/metal composites without using expensive and time-consuming adhesives or joining agents. Several specimens have been made and tested for their mechanical properties that show a gradual increase in fracture values with the addition of metal in mesh form. The process can be a strong candidate for the production of high-quality plastic/metal composites with tailored properties for specialized applications in the automotive and aerospace industries. The figures below show the working principle of the Hybrid Fused Deposition Modelling process and the composites that have been made from it.

Taken together, these activities clearly place me in the upper echelon with regards to academic and research activities in the field of 3D Printing/Additive Manufacturing. With the advent of new 3D printers and software packages, my expertise will continue to support and benefit the wider community.

References

- Butt, J., Ghorabian, M., Ahmed, A. and Shirvani, H., 2018. Finite element modelling and validation of thermomechanical behaviour for layered aluminium parts made by composite metal foil manufacturing. Journal of Composites Science, 2(4), p.68.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2018. Tensile lap-shear and flexural behaviour of aluminium metal foil parts made by composite metal foil manufacturing. Progress in Additive Manufacturing, pp.1-9.

- Butt, J., Shirvani, H., 2018. Experimental analysis of metal/plastic composites made by a new hybrid method. Additive Manufacturing, 22, 216–222.

- Butt, J., Onimowo, D.A., Gohrabian, M., Sharma, T. and Shirvani, H., 2018. A desktop 3D printer with dual extruders to produce customised electronic circuitry. Frontiers of Mechanical Engineering, 13(4), pp.528-534.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2018. Numerical and experimental analysis of product development by composite metal foil manufacturing. International Journal of Rapid Manufacturing, 7(1), pp.59-82.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2016. Microstructure and mechanical properties of dissimilar pure copper foil/1050 aluminium composites made with composite metal foil manufacturing. Journal of Materials Processing Technology 238, pp.96-107.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2016. Strength analysis of aluminium foil parts made by composite metal foil manufacturing. Progress in Additive Manufacturing, 1(1-2), pp.93-103.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2016. Rapid prototyping by heat diffusion of metal foil and related mechanical testing. The International Journal of Advanced Manufacturing Technology, 84(9-12), pp.2357-2366.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2015. Peel and tensile test investigation of aluminium 1050 foil parts made with a new additive manufacturing process. International Journal of Rapid Manufacturing, 5(1), pp.95-115.

- Butt, J., Mebrahtu, H. and Shirvani, H., 2015. A novel rapid prototyping process for the production of metal parts. International Journal of Advancements in Mechanical and Aeronautical Engineering– IJAMAE, 2(1), pp.15-18.